A2L refrigerants: industry must act now and be ready for the next F-Gas phasedown in 2021.

The Chemours Company to be ready for the next EU HFC F-Gas phasedown in 2021 by accelerating both the development of A2L-ready equipment and systems, and the adoption of commercially available A2L refrigerants. These refrigerants, defined as lower flammability compared to Class 2 or Class 3 fluids, deliver the benefit of low global warming potential (GWP) solutions with potential for use with higher charge sizes compared to Class 3 fluids such as hydrocarbons. To enable and support the adoption of A2L refrigerants, more training is required on their use, as well as increased knowledge and understanding of risk assessment methods.

Why action is needed now

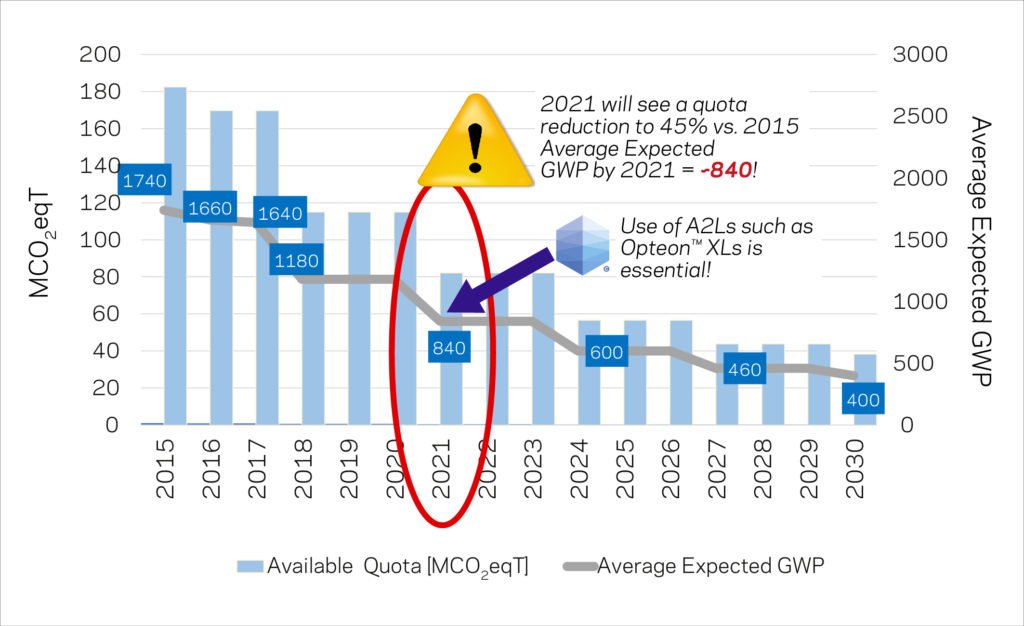

In January 2015, the F-Gas regulations went into effect in Europe to move the market towards lower GWP solutions in an effort to achieve important climate objectives. A cap and phasedown approach was introduced that limits the quantity of HFCs that can be placed on the EU market via a quota system, expressed in tonnes of CO2 equivalent based on a product’s GWP. This quota is reduced year after year resulting in lower availability and GWP-weighted pricing for high-GWP refrigerants such as R-404A and R-410A. Following the dramatic cut to the F-Gas quota in 2018, another significant reduction is due in 2021.

The HFC phasedown in 2021 (see Chart) reduces the available quota by 55% vs. the baseline – a significant reduction – and so the industry needs to be ready. But how? By using the lowest GWP refrigerant suitable for the application which has the optimum balance of properties including performance, environmental sustainability, safety and Total Cost of Ownership (TCO). In many cases, this will be an A2L refrigerant. A degree of flammability is often a necessary trade-off to obtain the lowest GWP products, without sacrificing capacity, efficiency, and economic sustainability of the total investment. These A2L refrigerants must be implemented in high volumes and on a large scale for the industry to have any chance of meeting the F-Gas phasedown.

Although the European F-Gas Regulation is working as designed to reduce the overall CO2 emissions from HFCs, only the first major step-down has been achieved. Looking forward, to successfully meet future step-down requirements and satisfy the market need, adoption of A2L refrigerants needs to increase rapidly. There are some challenges that must be addressed quickly, however. Recent broad reports of non-quota compliant imports point to the need for stricter enforcement of the regulation to ensure the climate objectives are met. To fully prepare the market for the subsequent F-Gas step-downs, safety standards need to be updated to appropriately reflect charge size differentiation and design/mitigation requirements between different levels of flammability. In addition, more training is required on the use of A2L refrigerants. Increasing the number of capable, qualified technicians, combined with increasing the knowledge base of risk assessment methods and interpretation of EN378 and IEC standards, will also enable and support the adoption of these lower GWP solutions.

Momentum is building

The good news is that awareness of the A2L products, their properties and characteristics is increasing. Guides are available from FETA, The Institute of Refrigeration (IoR) and the various equipment manufacturers. Component manufacturers are working in parallel with refrigerant suppliers such as Chemours to test and approve the new A2L blends. The first compressor prototypes are available or are entering field trials. Chillventa 2018 will also increase this number significantly as the manufacturers compete to bring their products to market.

Codes and standards are now in place, such as EN378 or IEC60533-2-40, to allow calculation of safe charge sizes of A2L refrigerants. Calculation guides are also available from contractor and trade associations. Regulations in the UK and Europe focus on Risk Assessment. A2L containing equipment is in scope, but the additional hazard of a flammable refrigerant needs to be considered too when installing equipment. The risk of creating and then igniting a flammable atmosphere needs to be assessed and mitigated. A2L refrigerants make this mitigation straightforward as they have higher Lower Flammable Limits (LFLs) and are more difficult to ignite than class A3 refrigerants. There are additional resources available through consultants and training establishments who can help with Risk Assessment.

There is also now more clarity on the road to adoption of A2L refrigerants and hydrofluoroolefin (HFO) refrigerant technology – technology that makes reaching those lower GWP targets mandated in the EU F-Gas regulation much easier. For new equipment, the range of products that meet these criteria has now been extended to include HFO-blends such as R-454A in refrigeration and R-454B in air conditioning.

How Chemours can help you

Chemours is ready to support you in transitioning to low-GWP refrigerants – from offering a full portfolio of low-GWP solutions to a broad network of Partner Distributors, to support from its Technology Experts. The Opteon™ XL range of refrigerants are low-GWP solutions that have been specifically developed to enable the European refrigerant market to comply with the ongoing F-Gas Regulation. The use of Opteon™ XL refrigerants in refrigeration, heat pump, chiller and air conditioning applications provides significant reductions in GWP (up to 99 per cent) compared to the legacy HFC refrigerants they replace.

What can I do?

Act now! A2L HFO technology is a reality and is playing a critical role in achieving climate objectives and business continuity. In refrigeration, there is an increasing number of case studies being published and major supermarket groups are moving forward with adoption as part of their long-term strategy. While these early adopters are encouraging, the rest of the market such as heat pumps must also demand A2L products through their suppliers to create even more demand and to help speed up availability of compatible equipment. New A2L-ready equipment and systems need to be developed and ready by the end of 2020. The challenge is real, but you can look to Opteon™ to help navigate the refrigerant landscape and come out on top.